By JAN LARSON McLAUGHLIN

BG Independent News

Decades ago, parents warned their children to get college degrees so they could avoid the dirty, repetitive work of manufacturing.

That is no longer the case.

“Our grandparents said, ‘Get your degree. Don’t go into manufacturing,’” said Lisa Wojtkowiak, senior talent learning and development manager at Betco.

But on Friday, Wojtkowiak and other Bowling Green manufacturers were telling students just the opposite.

“We make bubbles,” she said. “It’s not the old steel mills of the 1950s.”

Bowling Green Middle School students got a glimpse of modern manufacturing Friday during the annual manufacturing day. The event included representatives from Vehtek, Rosenboom, Lubrizol, Betco, Regal, GKN, Phoenix and Penta Career Center.

The students got to do learn about robots, virtual reality, heart dissections, density of liquids, helicopter designs and cleaning products.

“This is to show our students what modern manufacturing looks like,” said Jodi Anderson, secondary curriculum coordinator for Bowling Green City Schools. “We want to spark their interest in manufacturing as a career option.”

Penta Career Center display

Today’s manufacturing uses robotics not back-breaking labor.

“They may have had a grandparent who had a different experience with manufacturing,” Anderson said.

The annual manufacturing day at Bowling Green City Schools was introduced a couple years ago, when local plants started having trouble finding skilled workers.

“Manufacturers are in need of qualified workers,” Anderson said.

The event allows local manufacturers to introduce themselves to students before they’ve already chosen a career path.

“I think it’s important for manufacturers to introduce themselves to younger populations,” Wojtkowiak said. “The sooner we’re in their schools, the better.”

A student tries equipment from Betco.

College is no longer the only path to good-paying jobs, said Carol Espen, senior human resources manager with Regal.

“I hope that they recognize manufacturing is an exciting industry” for jobs in areas such as engineering and finance, Espen said.

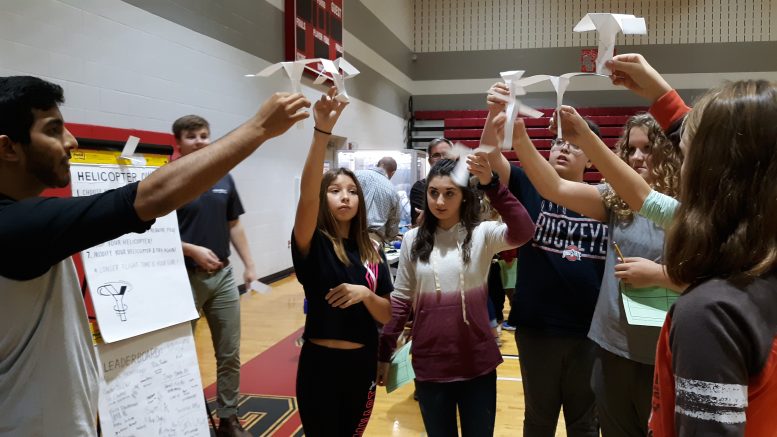

At the Regal display, students were making modifications to paper helicopter designs, then testing them to see which stayed airborne longer.

At the Lubrizol display, students learned about different liquid densities, by dropping items such as eggs, ping pong balls, bolts and dice into tap water and salt water.

“We’re hoping they leave with a little bit of excitement about STEM,” science, technology, engineering and math, said Lubrizol plant manager Matt Paquette.

Students drop items in different density liquids at Lubrizol table.

Nearby at the Rosenboom display, students were putting together hydraulic cylinders.

“They are learning how raw materials are turned into finished products,” said Sherry Hintz, head of Rosenboom human resources.”They are learning how to go into a real work environment.”

That hands-on work struck a chord with seventh grader Bradley Palmer, who said he was interested in building hydraulics.

“This is showing people about engineering in Bowling Green,” Palmer said.

Another seventh grader, Lydia Mullins, was eyeing the robotics.

“We’re learning about a different career instead of going to college,” Mullins said. “I love a lot of the tech things and being able to code the robots.”