By JAN LARSON McLAUGHLIN

BG Independent News

Bowling Green saw growth in all of its industrial and business parks last year – with companies reporting a total of $41 million in new machinery and equipment, and another $20 million in construction.

Members of the Bowling Green Economic Development Foundation met Wednesday to hear about the successes and struggles of growth in the city.

A speed bump to some growth has been the difficulty attracting and retaining employees, according to Sue Clark, executive director of the foundation. The difficulty has led many businesses to make investments in their sites for technology that replaces the need for additional people, she said.

“The labor force issues that have plagued us for the past couple of years remain,” Clark said. “It is still the number one issue on most companies’ minds.”

Local businesses have tried to adapt by adjusting their pay scales, adding incentives for employees, becoming more creative in their recruiting tactics, and making their corporate cultures more attractive to young workers, she said.

“We must work to change the stigma of manufacturing jobs as dirty, hard and low-paying,” Clark said. “Today’s manufacturers are clean, modern, high-tech and the pay is very competitive.”

Dr. Russell Mills, associate professor of political science at Bowling Green State University, spoke at the luncheon about the “Rise of the Robots: Automation and Workforce Development.”

In this region, industries have tried to combat the lack of an ample workforce with an increased reliance on robotics, he said.

“Automation is a fact of life here,” Mills said.

Mills also talked about the so called “brain drain,” encountered in Northwest Ohio – showing statistics of the number of people leaving here in their 20s, but then returning as they age.

“We produce a lot of people with some sort of degrees,” he said, referring to the education level of the region. “The challenge is, they leave.”

But Clark reported that local manufacturers are adapting, and are making efforts to attract workers.

“It is a very changing world, and these companies are changing with it,” she said.

Clark noted the local investments of $41 million in new equipment and machinery, and another $20 million in building additions.

“That’s a huge number,” she said.

Following is a list of the businesses that reported investments last year:

- Agas Americas: $200,000 investment.

- Apio Inc.: $550,000 investment, plus $4.45 million for a building addition.

- ARGO-HYTOS Inc.: $80,000 investment.

- Betco Corporation: $4.8 million, plus another $3 million for a building addition.

- Biofit Engineered Products: $5,000 investment.

- Centaur Tool & Die Inc.: $85,000 investment.

- Clark Fixture Technologies: $300,000 investment.

- Clean Water Service Inc.: $800,000 investment.

- CMC Group Inc./Daymark: $750,000 investment.

- Cooper: $1 million investment.

- DOWA THT America Inc.: $1.6 million investment.

- Huss Equipment Corporation: $5,000 investment.

- K&W Grinding Inc.: $28,000 investment.

- Lubrizol Advanced Materials: $1.4 million investment.

- Regal Beloit: $500,000 investment.

- MICC: $6,000 investment.

- Mid-Wood Inc.: $130,000 investment.

- NovaVision: $1 million investment.

- Ohio Logistics: $120,000 investment, plus $9 million for a building addition.

- Phoenix Technologies International LLC: $300,000 investment.

- Pinnacle Plastic Products: $400,000, plus $160,000 for a building addition.

- Pioneer Packing Co. Inc.: $30,000 investment.

- Poggemeyer Design Group: $80,000 investment.

- Rosenboom Machine & Tool Inc.: $1,005,414 investment.

- Southeastern Container Inc.: $2.1 million investment.

- TH Plastics: $2.5 million investment.

- TA Truck Service: $1 million investment, plus $2.2 million for building.

- Williams Industrial Service Inc.: $110,000 investment, plus $313,952 for building addition.

- Xorb LLC: $160,000 investment, plus $911,287 for building addition.

- Vehtek: $20 million investment.

Clark also talked about efforts with the city’s public utilities department to direct economic development where it belongs.

“Where do we want to see the growth happen, and what kind of growth do we want to see in the community,” she asked.

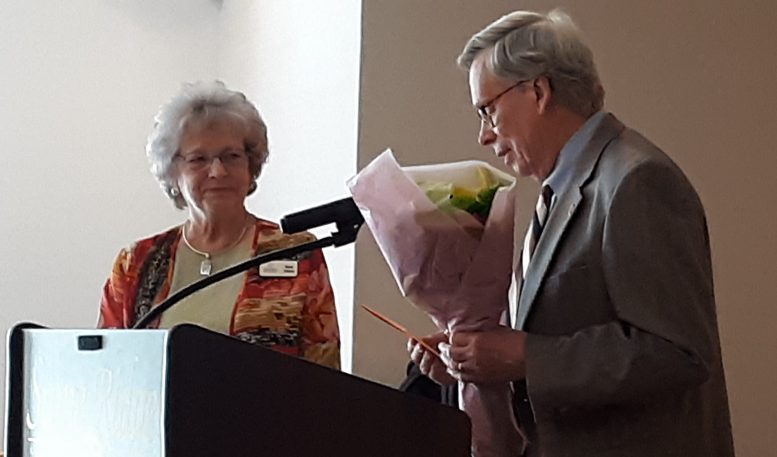

Also at the annual meeting, the foundation awarded Mayor Dick Edwards with the “Friend of Economic Development” award. Clark described how during annual visits to local manufacturers, the mayor consistently shows great interest in the products made and the history of the companies.

“Six months or a year later, he could recall that information,” Clark said of the mayor.

Edwards also isn’t afraid to take positions on issues that may not be easy or popular – such as pipelines, fracking or welcoming immigrants.

“He always studies the issues very carefully, and then takes a position,” Clark said.

Edwards is the third mayor that Clark has worked with on economic development issues.

“Each mayor brings a different trait and personality,” and with Edwards those include a keen interest in people, a cheerful attitude, and a commitment to accuracy.

Even when leading groundbreakings in freezing cold weather, “he remained his friendly, gracious self,” Clark said of Edwards.