By JULIE CARLE

BG Independent News

Some Bowling Green Middle School students pushed their hands deep in a container of water beads to feel the squishiness, but also to understand the process Principle Business Enterprises (PBE) uses to create some of their absorption-based products.

Karen Gambrell and Don Turner of Southeastern Container (SEC) handed out small, 4-inch clear plastic objects and wowed the student when they explained that the Bowling Green plant uses heat and air to turn the small “preform” into a 12-oz Coca-Cola bottle.

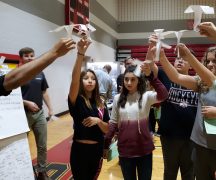

PBE and SEC were among the 10 local companies represented at Manufacturing Day Thursday at the middle school. The event introduced students to the variety of manufacturing opportunities that are available in and near their community.

All of the approximately 600 middle school students and a handful of high school classes had the opportunity to talk with company representatives throughout the day. The middle schoolers’ assignment was to visit the tables to learn about the companies. They wrote down company names, what they produced and an interesting fact about the company.

For the high school students who are further along in their career exploration, were more focused on what kind of jobs were available and the requirements.

Many of the companies offered giveaways, from candy to company swag, to provide another incentive for students to stop by.

At the Campbell’s table, the only company from a city other than Bowling Green, students flocked around the table trying to answer trivia to earn prizes.

“How many products does Campbell’s make?” asked Jerri Ryan, human resources associate, and Jennifer Mengerink, talent acquisition manager.

One group guessed numbers between 10 and 100 and was surprised to find out that more than 180 products are manufactured at Campbell’s plants across the country. In addition to soups, Pace salsa, Prego pasta sauces, and V8 beverages—produced at the Napoleon plants—Campbell’s brands include Goldfish, Pepperidge Farms, Pop Secret, Emerald Nuts and Pretzel Crisps.

“We like to showcase the opportunities available at Campbell’s,” Mengerink said. While they often attend job fairs and events at high schools and colleges, being able to talk to middle school students is a way to bring awareness about the company. “We are proud of the internship opportunities that are very project-based that often can lead to careers in engineering, manufacturing, human resources and communications,” she said.

Cassandra Mulinix, Tammy Myers and Matt Vielhaber, representing Bowling Green-based A-Gas, were at Manufacturing Day “to inspire the next generation and share potential career paths in our industry,” reported a company social media post. They handed out color-changing drinking cups and explained the company’s work.

Vielhaber said, “We recycle refrigerants, and help prevent global warming” by acquiring refrigerants from clients and separating out the gas, preventing its release into the atmosphere.

A hands-on experiment at the Betco table demonstrated, “Science is cool,” said Alycia Pittinger. The analytical chemist, whose company makes plant-based cleaning products that range from disinfectants to floor waxes, said students could see how chemistry works when a small bottle with clear liquid turned blue after they added citric acid crystals.

“We are pleased with the turnout of the companies that are here,” said BG Middle School Principal Eric Radabaugh. “This is good exposure for the students as they start exploring what life is after high school. They also learn about skills that they can apply in their classes as well as outside of school.”